Baldor Electric Company introduces Dodge D-LAG conveyor pulleys, a line of stock conveyor pulleys than can lower total cost of ownership. D-LAG conveyor pulleys utilize a cutting edge natural rubber compound that is 73 percent more resistant to wear than standard SBR rubber.

By increasing lagging life, Baldor’s Dodge D-LAG conveyor pulleys will extend the operating life of both the conveyor pulley and conveyor belt. The lagging is 100 percent vulcanized for pulley bonding and strength, making it resistant to cuts and gouges. Idling Pulley

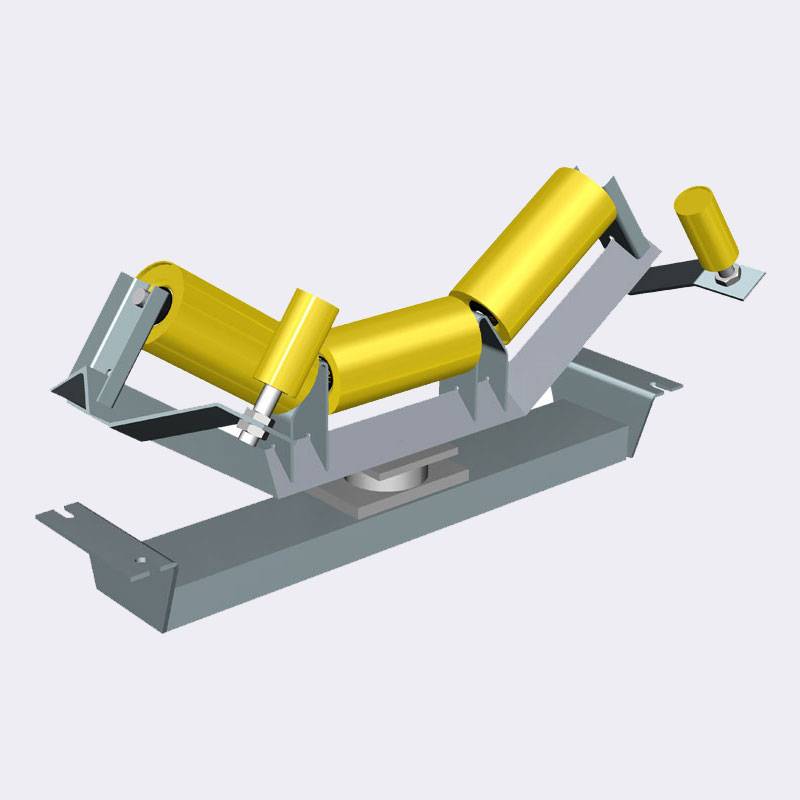

Two pulley styles are available from stock for next day delivery; D-LAG heavy-duty drum pulleys from 10” to 24” diameter, and D-LAG MDX (mine duty extra) drum pulleys from 12” up to 24” diameter. Baldor’s Dodge heavy-duty pulleys are designed with flexible end discs to eliminate weld fatigue under cyclical loads, while Dodge MDX pulleys feature an integral hub design that eliminates the welded hub.

Independent testing in 2012 showed D-LAG significantly outperformed other rubber formulas when subjected to abrasive conditions.

Baldor Electric Company www.baldor.com

Browse the most current issue of Design World and back issues in an easy to use high quality format. Clip, share and download with the leading design engineering magazine today.

Top global problem solving EE forum covering Microcontrollers, DSP, Networking, Analog and Digital Design, RF, Power Electronics, PCB Routing and much more

The Engineering Exchange is a global educational networking community for engineers. Connect, share, and learn today »

Conveyor Belt Roller Bearings Copyright © 2024 WTWH Media LLC. All Rights Reserved. The material on this site may not be reproduced, distributed, transmitted, cached or otherwise used, except with the prior written permission of WTWH Media Privacy Policy | Advertising | About Us