National Defense provides authoritative, non-partisan coverage of business and technology trends in defense and homeland security. A highly regarded news source for defense professionals in government and industry, National Defense offers insight and analysis on defense programs, policy, business, science and technology. Special reports by expert journalists focus on defense budgets, military tactics, doctrine and strategy.

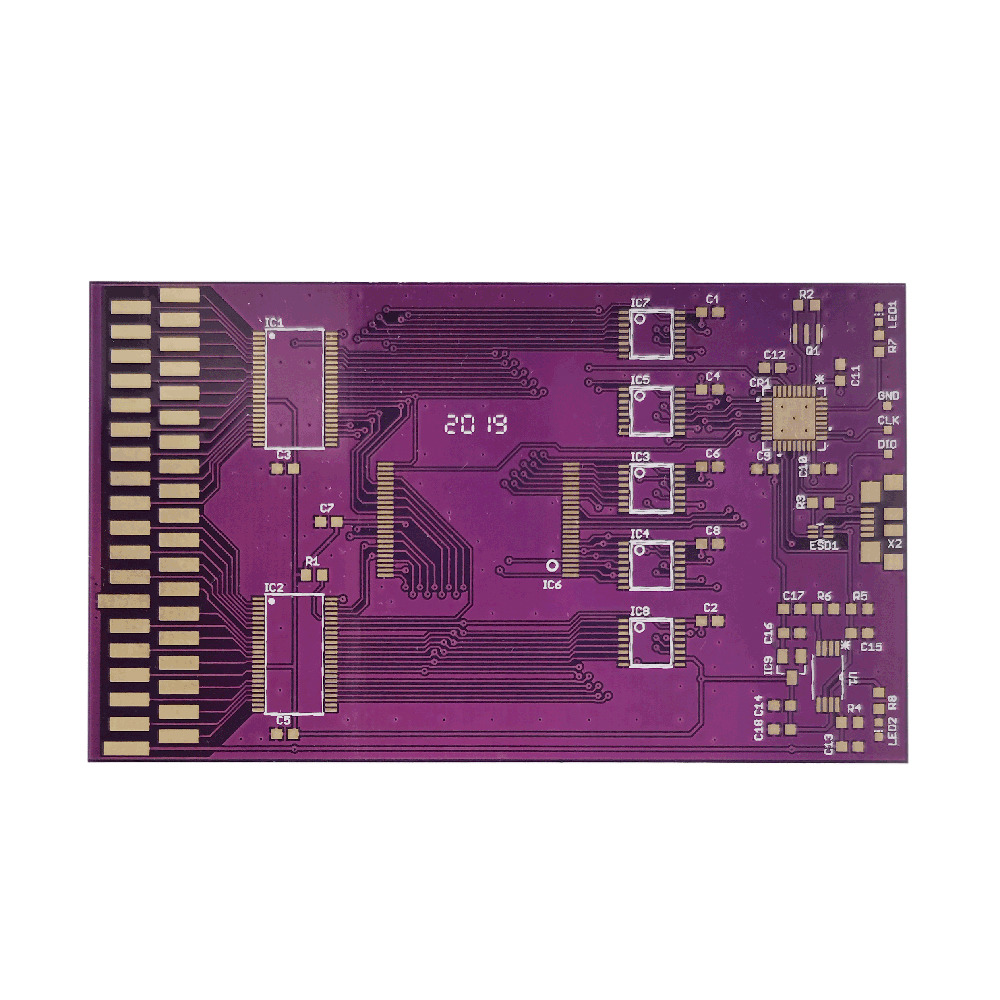

Every industry that makes modern life possible relies on a microelectronic stack consisting of computer chips, substrates and printed circuit boards, or PCBs. OEM Pcb Control Board Supplier

Nowhere is this more prevalent than in the defense industrial base. Everything, from night-vision goggles to F-35s, relies on multiple microelectronics.

Most of the manufacturing and know-how for PCBs and substrates left U.S. shores many years ago and migrated to countries with low-cost labor and significant government subsidies.

While this may have been a good financial strategy for the short term, the long-term consequences have been grave. U.S. national defense and economic security are at risk because the nation relies so heavily on adversaries and geopolitical competitors for the technologies that buttress military systems.

Congress recognized this issue with semiconductors and last year — after almost five years of deliberation — passed the CHIPS and Science Act. Lawmakers raised the alarm because the U.S. share of the world’s supply of chips had fallen to just 13 percent.

What was lost in the legislative process was the rest of the microelectronics stack: substrates connect a computer chip to a printed circuit board, which in turn connects to an electronic device. Chips don’t function without those two components. And if we thought 13 percent was an alarming statistic, the numbers for PCBs are even scarier. We now make only 4 percent of the world supply of PCBs and less than 1 percent of the substrates.

What this means is that most of the new U.S. chip fabrication facilities being built with CHIPS Act funding and the private investments that followed will produce chips that will be shipped to Asia to be packaged with substrates and printed circuit boards.

Without creating a more robust manufacturing capability for PCBs and substrates, the CHIPS Act is not improving the security and resiliency of our supply chain.

Beyond the logistical challenges of shipping microelectronics back and forth across the Pacific is the matter of security. The microelectronics that power national security systems and critical infrastructure must be trusted and secure. With 90 percent of the world’s PCBs being made in Asia — 56 percent in China and 13 percent in Taiwan — along with almost 100 percent of the substrates, there is risk of bad actors adding unwanted “phone home” and “kill switch” capabilities that would allow them to interfere with the most sensitive national defense and infrastructure systems.

Not all microelectronics require such rigorous vetting and trust. Having a long supply chain works for garage door openers and toasters, but it is unacceptable for national defense systems and critical infrastructure.

Fortunately, many of the most sensitive microelectronics for the defense industry are made in America, but most of the second- and third-tier suppliers of commercial-off-the-shelf components come from Asia, and more than half come from China alone.

That latter point is addressed in the National Defense Authorization Act. By 2027, Congress will require the Pentagon to have a plan to remove microelectronic components made in China, Russia, Iran and North Korea. The year 2027 may sound like a long way off, but accomplishing what Congress is mandating will be a significant pivot for many large original equipment manufacturers.

In addition to sticks, there are also important carrots in play. The Defense Department has begun distributing funding through the Defense Production Act. Several companies have announced plans to invest in additional capacity. But more is needed.

It will take years for the domestic microelectronics industry to scale up to decrease reliance on other nations. That is why the Printed Circuit Board Association of America has been advocating for H.R. 3249, the Protecting Circuit Boards and Substrates Act, which would provide $3 billion for research and development, facilities and workforce development and a 25 percent tax incentive for companies buying American-made printed circuit boards and substrates.

The association also promotes a healthy Defense Production Act budget to address increasing domestically sourced microelectronics. Just as the CHIPS Act funding attracted private investment, the Protecting Circuit Boards and Substrates Act would likewise energize an industry that has shrunk to its current unacceptable state.

National Defense Industrial Association member companies and suppliers have a major stake in this industry, and we hope they will join the Printed Circuit Board Association of America in supporting legislation and policies that bring the microelectronics ecosystem back in balance.

The United States needs reliable, secure and trusted sources for the microelectronics ecosystem to protect national and economic security. ND David Schild is the executive director of the Printed Circuit Board Association of America.

"It will take years for the domestic microelectronics industry to scale up to decrease reliance on other nations." And we're to trust and rely on the idiots responsible for this?

Double Layer Pcb 2101 Wilson Blvd, Suite 700 Arlington, VA 22201 tel: (703) 522-1820